Have you ever wondered how to save time and money in your agricultural business? If you own a farm or work in the agricultural sector in Egypt, especially in exporting agricultural products, this article is for you.

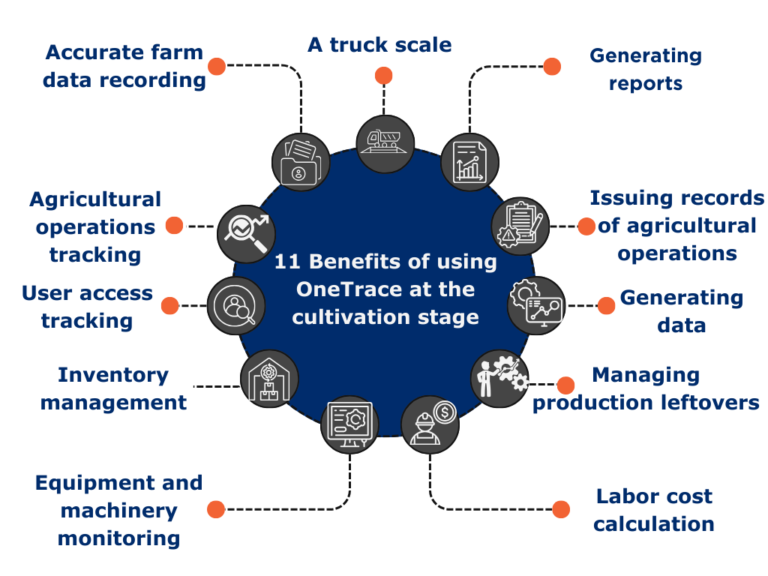

Let’s take a closer look at the OneTrace tracking system developed by GS1. This innovative system transforms your farm or agricultural business into a dynamic hub supported by data that can translate into streamlined operations and significant financial gains.